To Ensure You Are Able To Get The Most Out Of Your Linear Actuator S

Choosing The Correct Power Supply For Your Linear Actuator Power To ensure you are able to get the most out of your linear actuator (s) it is vital you choose an appropriate power supply. we offer several different power supplies; this tutorial is aimed at assisting you in selecting the one that best fits your needs. power supply options: 12v battery or 12v car battery. 12v 5a ac to dc wall converter. The stroke length of an actuator is the measurement of how much it moves when activated. for example, the length of a pa 14 unit with a 6 inch stroke will be 10.85 inches when fully retracted. once activated, the unit will extend 6 inches to its final length of 16.85 inches. our linear actuators come with a built in limit switch, to stop the.

Tips To Extend Your Linear Actuators Lifespan Linear Actuator If there is no resolution. at progressive automations we have a team of highly skilled engineers who will be able to assist you with further troubleshooting steps and take corrective action if required. please email us at sales@progressiveautomations or give us a call at 1 800 676 6123 for further assistance. Ensure they are tightened to the manufacturer’s recommended torque specifications. for clevis mounts, insert the clevis pin through the holes on the actuator and the bracket, securing it with a cotter pin or retaining clip. 4. position the actuator. carefully lift the actuator and position it within the mounting brackets. Method 1. the most common method to mount your linear actuator is the dual pivot mounting method. this common mounting arrangement consists of mounting the linear actuator on both ends with a free to pivot mounting point usually involving a clevis and mounting pin. this mounting method allows the actuator to pivot on both sides as the actuator. Selecting the right linear actuator for your application involves accounting for the necessary speed, load, stroke length, and more. shawn hakim. building a successful linear motion system starts.

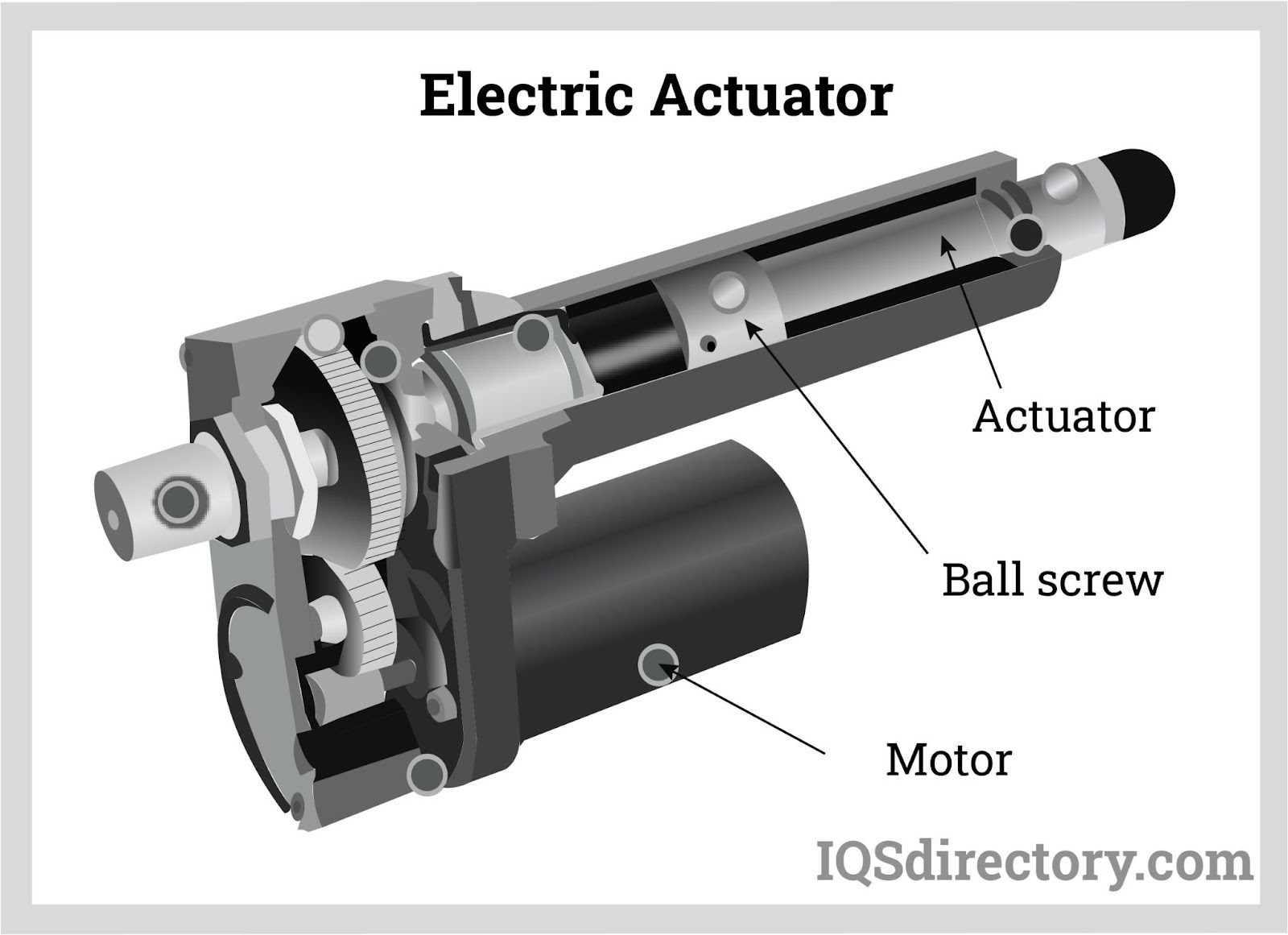

To Ensure You Are Able To Get The Most Out Of Your Linear Actuator S Method 1. the most common method to mount your linear actuator is the dual pivot mounting method. this common mounting arrangement consists of mounting the linear actuator on both ends with a free to pivot mounting point usually involving a clevis and mounting pin. this mounting method allows the actuator to pivot on both sides as the actuator. Selecting the right linear actuator for your application involves accounting for the necessary speed, load, stroke length, and more. shawn hakim. building a successful linear motion system starts. White paper. a linear actuator is a self supporting structural system capable of transforming a circular motion into a linear motion. this motion is generated by a motor, and sends the movement (or force) along an axis. in this way, linear actuators operate differently than conventional electric motors, which work in a circular motion. A linear actuator is a device that converts rotational motion into linear motion in order to move objects in a straight line. they typically consist of an electric motor and a lead, ball, or roller screw which translates the rotary motion of the motor into linear motion. when the motor is activated, it rotates the screw, which moves the nut or.

Learn Everything About Types Of Linear Actuators 2023 White paper. a linear actuator is a self supporting structural system capable of transforming a circular motion into a linear motion. this motion is generated by a motor, and sends the movement (or force) along an axis. in this way, linear actuators operate differently than conventional electric motors, which work in a circular motion. A linear actuator is a device that converts rotational motion into linear motion in order to move objects in a straight line. they typically consist of an electric motor and a lead, ball, or roller screw which translates the rotary motion of the motor into linear motion. when the motor is activated, it rotates the screw, which moves the nut or.

Comments are closed.