This 55 Step Process Is How A New Balance Sneaker Is Made

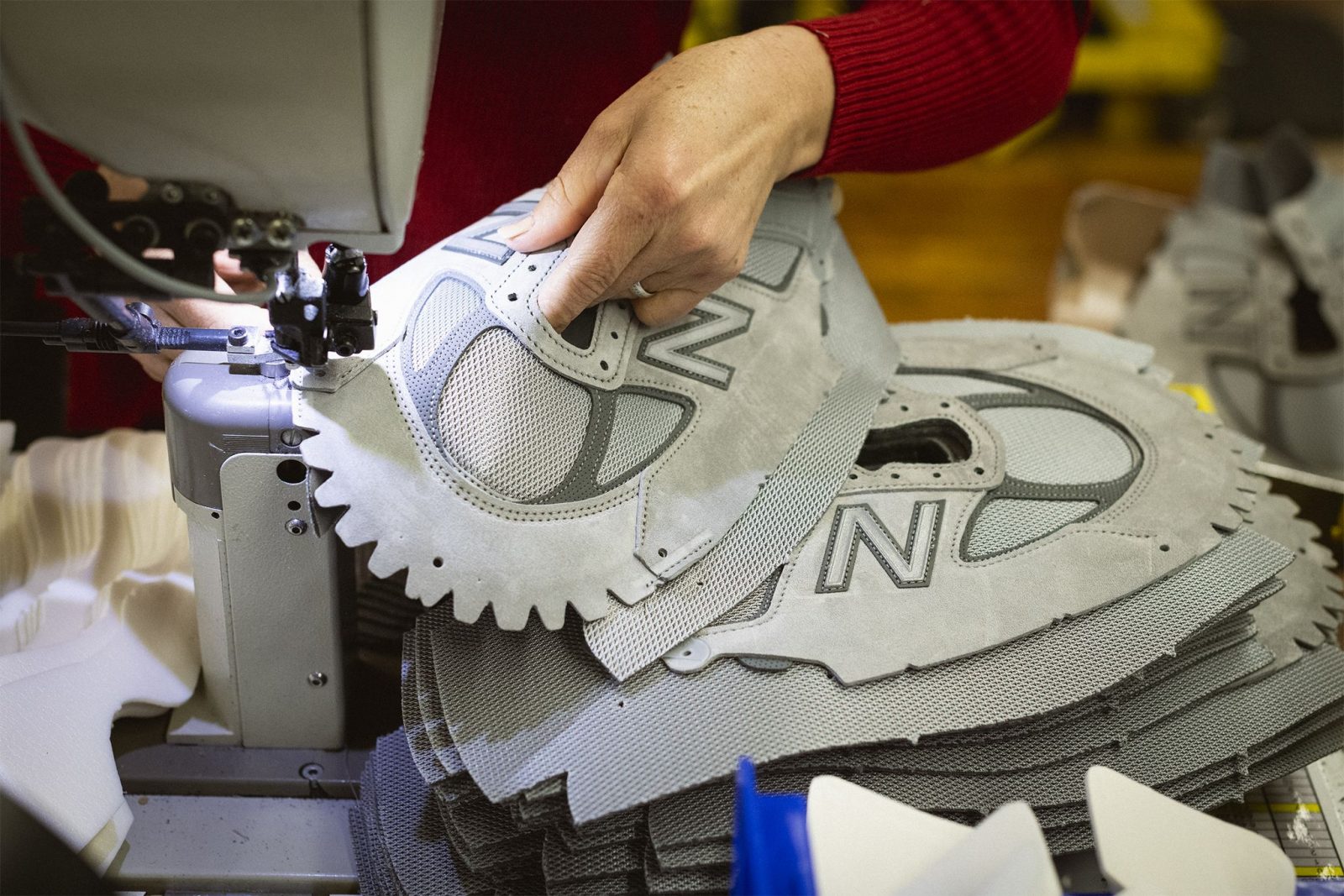

This 55 Step Process Is How A New Balance Sneaker Is Made Every new balance sneaker created at one of the company’s five new england based factories moves quickly, stopping at each worker for an average of just 22.5 seconds. of the 55 step process. The shoe is laced, tagged, cleaned, and inspected. it is even made to go through a small metal detector for ensuring that no unwanted material is in it. once it clears the quality control, the shoe is boxed and sent for distribution. the 55 step process is completed in three hours, starting from cutting to packing.

This 55 Step Process Is How A New Balance Sneaker Is Made New balance wasn’t always considered the “cool shoe,” as most sneakerheads turned towards nike or adidas. however, as of late, more and more people are choos. Making a new balance sneaker takes 50 to 60 steps, and work is divided into four stations: the prep station, initial stitching, hand stitching, and the assembly station. it's at the fourth station. Most new balance shoes are made by cold cement construction process. the new balance classic trainer styles have a sheet cut eva midsole. this midsole is attached by the cold cement process. cold cement is the modern updated style of shoe construction. cold cement is the opposite of the classic high heat vulcanized shoe construction, as found. New balance inside the factory shoes documentary eng.

This 55 Step Process Is How A New Balance Sneaker Is Made Most new balance shoes are made by cold cement construction process. the new balance classic trainer styles have a sheet cut eva midsole. this midsole is attached by the cold cement process. cold cement is the modern updated style of shoe construction. cold cement is the opposite of the classic high heat vulcanized shoe construction, as found. New balance inside the factory shoes documentary eng. @cole stp and @dyvisuals of thisisthedream head over to the new balance store in new york city and gather insight as to how their sneakers are made. Made in usa. new balance's roots lie in the united states, where it all began in 1906. the brand has a strong commitment to domestic manufacturing, emphasizing quality and supporting local communities. the two u.s. factories are in massachusetts and maine, each showcasing a dedication to traditional craftsmanship and attention to detail.

This 55 Step Process Is How A New Balance Sneaker Is Made @cole stp and @dyvisuals of thisisthedream head over to the new balance store in new york city and gather insight as to how their sneakers are made. Made in usa. new balance's roots lie in the united states, where it all began in 1906. the brand has a strong commitment to domestic manufacturing, emphasizing quality and supporting local communities. the two u.s. factories are in massachusetts and maine, each showcasing a dedication to traditional craftsmanship and attention to detail.

This 55 Step Process Is How A New Balance Sneaker Is Made

Comments are closed.