The Initial Proposal Of The Model For Risk Approach Based On Pdca Cycle

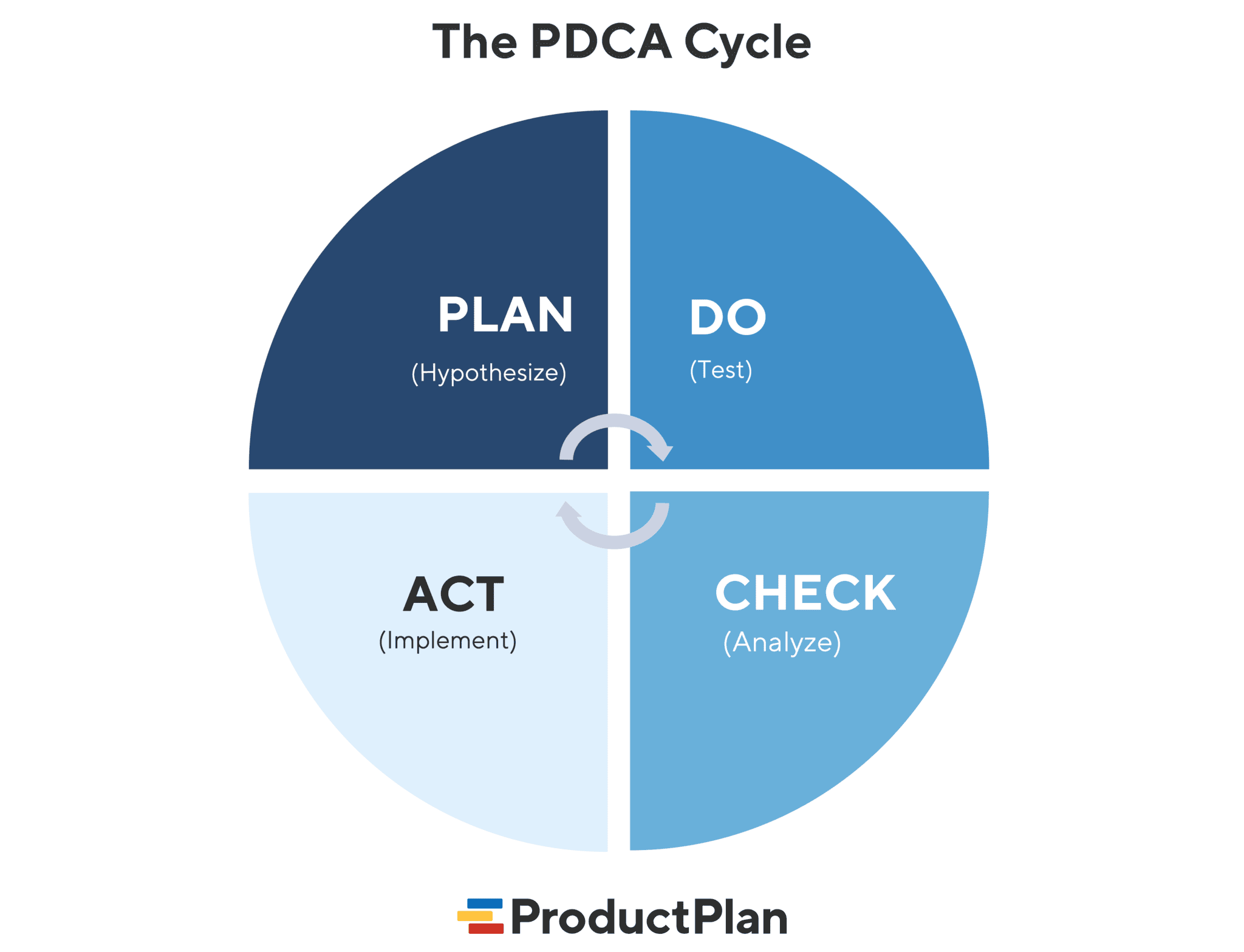

The Initial Proposal Of The Model For Risk Approach Based On Pdca Cycle Download scientific diagram | the initial proposal of the model for risk approach based on pdca cycle (plan, do, check, act). from publication: from theory to practice: a risk management model for. Understand the evolution of these variations. the plan do check act cycle (figure 1) is a four step model for carrying out change. just as a circle has no end, the pdca cycle should be repeated again and again for continuous improvement. the pdca cycle is considered a project planning tool. figure 1: plan do check act cycle.

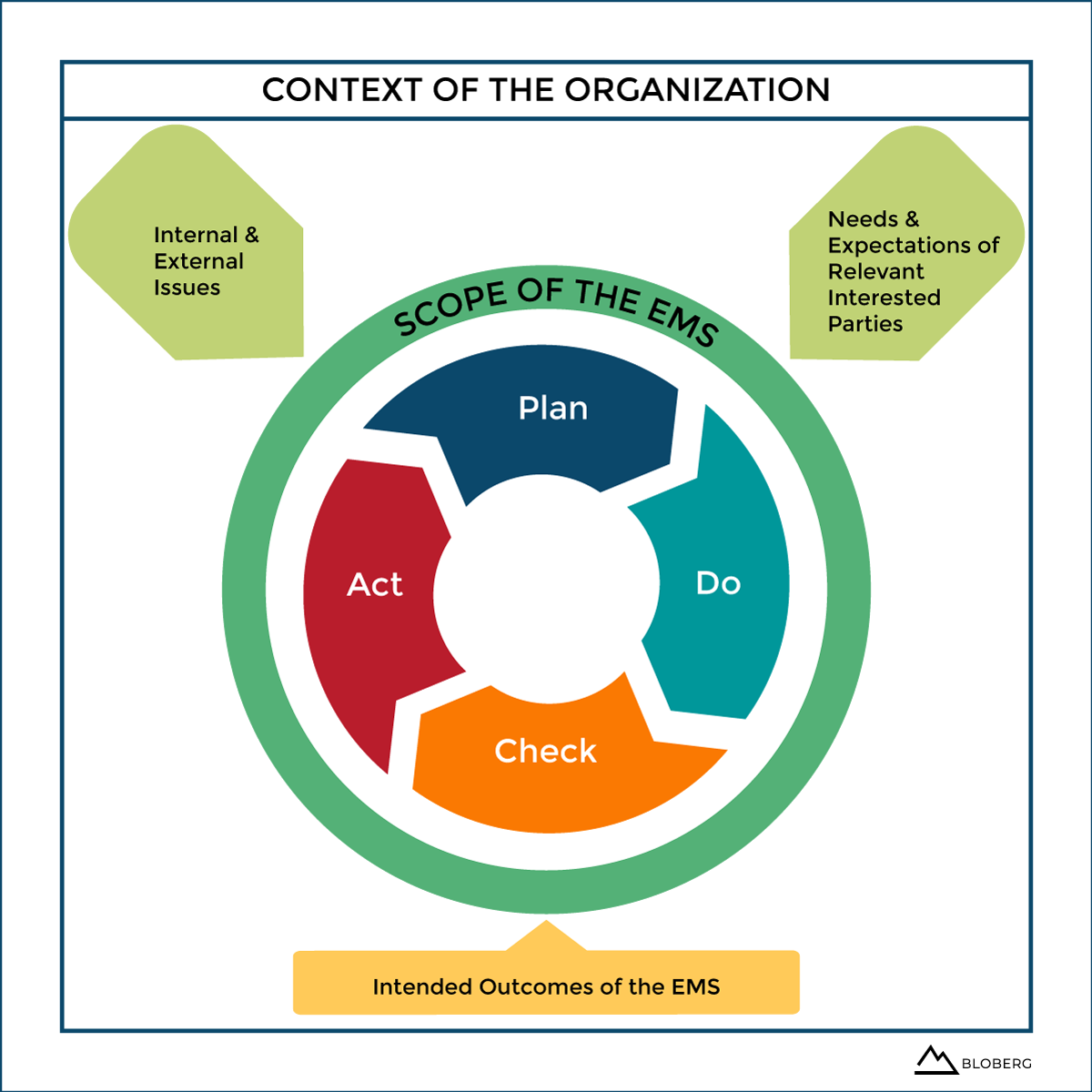

Iso 9001 Pdca Cycle The pdca cycle is a process improving method that involves a continuous loop of planning, doing, checking, and acting. each stage of the pdca, meaning the plan do check act, cycle contributes to the goal of identifying which business processes work and which of them need further improvement. this methodical approach is also utilized to avoid. The pdca cycle is a four step method used to improve processes and systems. the steps are plan, do, check, and act. 2. where did the pdca cycle originate? the pdca cycle has its roots in the early 20th century, introduced by walter shewhart and further refined by dr. w. edwards deming. 3. can the pdca cycle be used outside of manufacturing?. One such approach is the pdca (plan do check act) cycle, a simple yet powerful methodology. in this article, we’ll explore how the pdca cycle can be effectively leveraged in the context of iso 27001. plan – laying the foundation; defining objectives and scope: the ‘plan’ phase of the pdca cycle begins with setting clear objectives for. The pdca cycle is a powerful tool in the project manager's arsenal, providing a structured approach to problem solving and continuous improvement. teams can use the method to navigate complexities with agility and confidence, initiate change, mitigate risk and improve performance, driving project success in an ever evolving landscape.

Pdca Cycle Model One such approach is the pdca (plan do check act) cycle, a simple yet powerful methodology. in this article, we’ll explore how the pdca cycle can be effectively leveraged in the context of iso 27001. plan – laying the foundation; defining objectives and scope: the ‘plan’ phase of the pdca cycle begins with setting clear objectives for. The pdca cycle is a powerful tool in the project manager's arsenal, providing a structured approach to problem solving and continuous improvement. teams can use the method to navigate complexities with agility and confidence, initiate change, mitigate risk and improve performance, driving project success in an ever evolving landscape. Plan do check act cycle (pdca) is a four step, iterative by design method used for control and continual improvement of processes and products. it is also known as the plan do study act (pdsa) cycle, deming cycle, control circle cycle or the shewhart cycle. the pdca cycle (image source: shutterstock [1]) pdca is an evidence based participatory. The plan do check act (pdca) model, also known as the deming wheel or the deming cycle, is an iterative method for continual improvement of processes, products, or services and is a key element of lean management. the pdca model was developed in the 1950s by william deming as a learning or improvement process based on the scientific method of.

Comments are closed.