Pt Lesson 13 Limits Fits And Tolerance Pdf Engineering

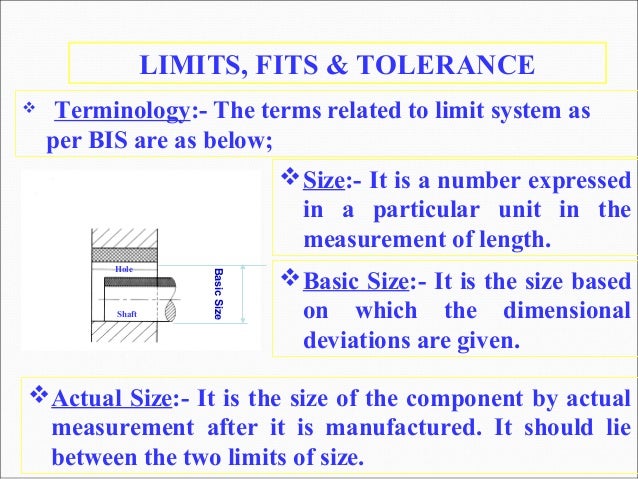

Pt Lesson 13 Limits Fits And Tolerance Pdf Engineering Limits, fits and tolerance | pdf | engineering tolerance | surface roughness. pt lesson 13. limits, fits and tolerance free download as pdf file (.pdf), text file (.txt) or read online for free. this document discusses limits, fits, and tolerances in manufacturing. it defines limits as the extreme permissible sizes of a part, fits as the. Lesson 13. limits, fits and tolerance. 1.1 limits fits and tolerance. two extreme permissible sizes of a part between which the actual size is contained are called limits. the relationship existing between two parts which are to be assembled with respect to the difference on their sizes before assembly is called a fit.

Limit Fit Tolerance Pdf Engineering Tolerance Teaching Mathemati Pt lesson 13. limits, fits and tolerance free download as pdf file (.pdf), text file (.txt) or read online for free. Evaluate limits and fits for an assembly pair 6 h7 g6 mm solution: the size 6 mm lies in the diameter step of 3 6. the fundamental tolerance unit is = 0.7327 μm tolerance for hole h7 tolerance = 16i = 12 μm the fundamental deviation h hole = zero tolerance for g6 shaft tolerance = 10i = 8 μm. Evaluate limits and fits for a pair of –diameter 6 h7 g6 solution: the size 6 mm lies in the diametral step of 3 6, therefore, d is given by – the value of fundamental tolerance unit is given by – limits of tolerance for hole h7 the standard tolerance is –16 i = 16x0.7327 = 11.72 = 12 µm the fundamental deviation h hole is –0. Which limits are fixed actual size – measured size . 2,3 limits – maximum and minimum permissible sizes. 4,5 deviation – max. and min. difference from a nominal size (1 2 or 1 3) 6 tolerance – total allowable variance in dimensions (upper limit – lower limit . or . 2 3 or 4 5).

Limit Fit Tolerance Evaluate limits and fits for a pair of –diameter 6 h7 g6 solution: the size 6 mm lies in the diametral step of 3 6, therefore, d is given by – the value of fundamental tolerance unit is given by – limits of tolerance for hole h7 the standard tolerance is –16 i = 16x0.7327 = 11.72 = 12 µm the fundamental deviation h hole is –0. Which limits are fixed actual size – measured size . 2,3 limits – maximum and minimum permissible sizes. 4,5 deviation – max. and min. difference from a nominal size (1 2 or 1 3) 6 tolerance – total allowable variance in dimensions (upper limit – lower limit . or . 2 3 or 4 5). Fits and tolerances . figure 1.3: basic hole and shaft system . an interference fit results in an interference between two . mating parts under all tolerance conditions. a clearance fit results in a clearance between the two . mating parts under all tolerance conditions. a transition fit results in either a clearance or an. Grade of tolerance: it is an indication of the level of accuracy. there are 18 grades of tolerances – it01, it0, it1 to it16 it01 to it4 for production of gauges, plug gauges, measuring instruments. it5 to it 7 for fits in precision engineering applications. it8 to it11 – for general engineering.

Limits Fits And Tolerances Types Explained With Diagram Fits and tolerances . figure 1.3: basic hole and shaft system . an interference fit results in an interference between two . mating parts under all tolerance conditions. a clearance fit results in a clearance between the two . mating parts under all tolerance conditions. a transition fit results in either a clearance or an. Grade of tolerance: it is an indication of the level of accuracy. there are 18 grades of tolerances – it01, it0, it1 to it16 it01 to it4 for production of gauges, plug gauges, measuring instruments. it5 to it 7 for fits in precision engineering applications. it8 to it11 – for general engineering.

Limits Fits And Tolerance Pdf Engineering Tolerance Mechanical

Comments are closed.