Pt Lesson 13 Limits Fits And Tolerance

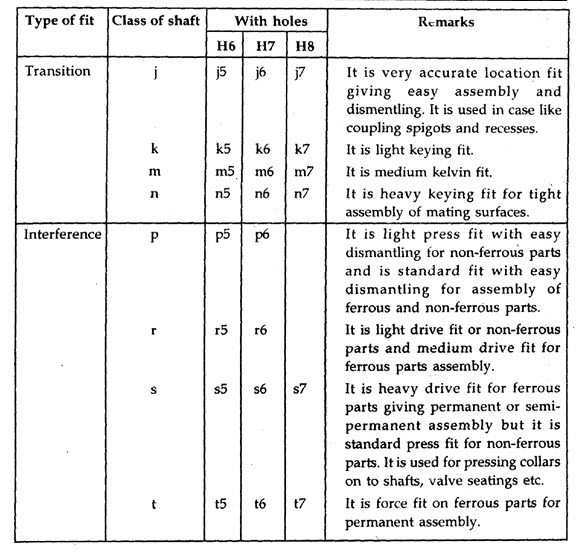

Pt Lesson 13 Limits Fits And Tolerance Lesson 13. limits, fits and tolerance. 1.1 limits fits and tolerance. two extreme permissible sizes of a part between which the actual size is contained are called limits. the relationship existing between two parts which are to be assembled with respect to the difference on their sizes before assembly is called a fit. Pt lesson 13. limits, fits and tolerance free download as pdf file (.pdf), text file (.txt) or read online for free. this document discusses limits, fits, and tolerances in manufacturing. it defines limits as the extreme permissible sizes of a part, fits as the relationship between sizes of parts to be assembled, and tolerance as the total.

Pt Lesson 13 Limits Fits And Tolerance Pdf Engineering In this lecture one can learn, what is a fit, what are different types of fit, what is the deviation and what is tolerances. it can also be learnt i.e., how. Pt lesson 13. limits, fits and tolerance free download as pdf file (.pdf), text file (.txt) or read online for free. scribd is the world's largest social reading and publishing site. Limits, fits and tolerances have always been a very commonly discussion topic in mechanical engineering design. through this video, i am trying to explain al. Ion of the tolerance zone in relation to the zero line.allowance: it is the intentional difference between the. ole dimensions and shaft dimension for any type of fit.size of tolerance: it is the di. the maximum and minimum limits of size.system of fitsfit is an assembly condition between ‘hole. & ‘shaft’ hole: a feature engulfing a co.

Pt Lesson 13 Limits Fits And Tolerance Limits, fits and tolerances have always been a very commonly discussion topic in mechanical engineering design. through this video, i am trying to explain al. Ion of the tolerance zone in relation to the zero line.allowance: it is the intentional difference between the. ole dimensions and shaft dimension for any type of fit.size of tolerance: it is the di. the maximum and minimum limits of size.system of fitsfit is an assembly condition between ‘hole. & ‘shaft’ hole: a feature engulfing a co. 1.unilateral tolerances: if the variation permitted is at only one side of the given dimension, called unilateral tolerance. when the variation permitted is at only one side of the given dimension, then it is slightly difficult to manufacture the components. hence the cost of manufacturing will be high. ex: mating parts. Evaluate limits and fits for a pair of –diameter 6 h7 g6 solution: the size 6 mm lies in the diametral step of 3 6, therefore, d is given by – the value of fundamental tolerance unit is given by – limits of tolerance for hole h7 the standard tolerance is –16 i = 16x0.7327 = 11.72 = 12 µm the fundamental deviation h hole is –0.

Pt Lesson 13 Limits Fits And Tolerance 1.unilateral tolerances: if the variation permitted is at only one side of the given dimension, called unilateral tolerance. when the variation permitted is at only one side of the given dimension, then it is slightly difficult to manufacture the components. hence the cost of manufacturing will be high. ex: mating parts. Evaluate limits and fits for a pair of –diameter 6 h7 g6 solution: the size 6 mm lies in the diametral step of 3 6, therefore, d is given by – the value of fundamental tolerance unit is given by – limits of tolerance for hole h7 the standard tolerance is –16 i = 16x0.7327 = 11.72 = 12 µm the fundamental deviation h hole is –0.

Comments are closed.