Pneumatic Air Hose Fittings At Gina Willis Blog

Pneumatic Air Hose Fittings At Gina Willis Blog Prepare for connection: if you have quick connect fittings, simply ensure the male end is ready to be inserted into the female end. for threaded connections, prepare your wrenches or pliers for tightening. connect the fittings: for quick connect fittings, insert the male end into the female end until you hear a click. They feature a push to connect mechanism that allows tubing to be inserted easily into the fitting, creating a secure and leak free connection. push to connect fittings are ideal for applications where rapid installation and disassembly are required, making them commonly used in air fitting assemblies for pneumatic systems.

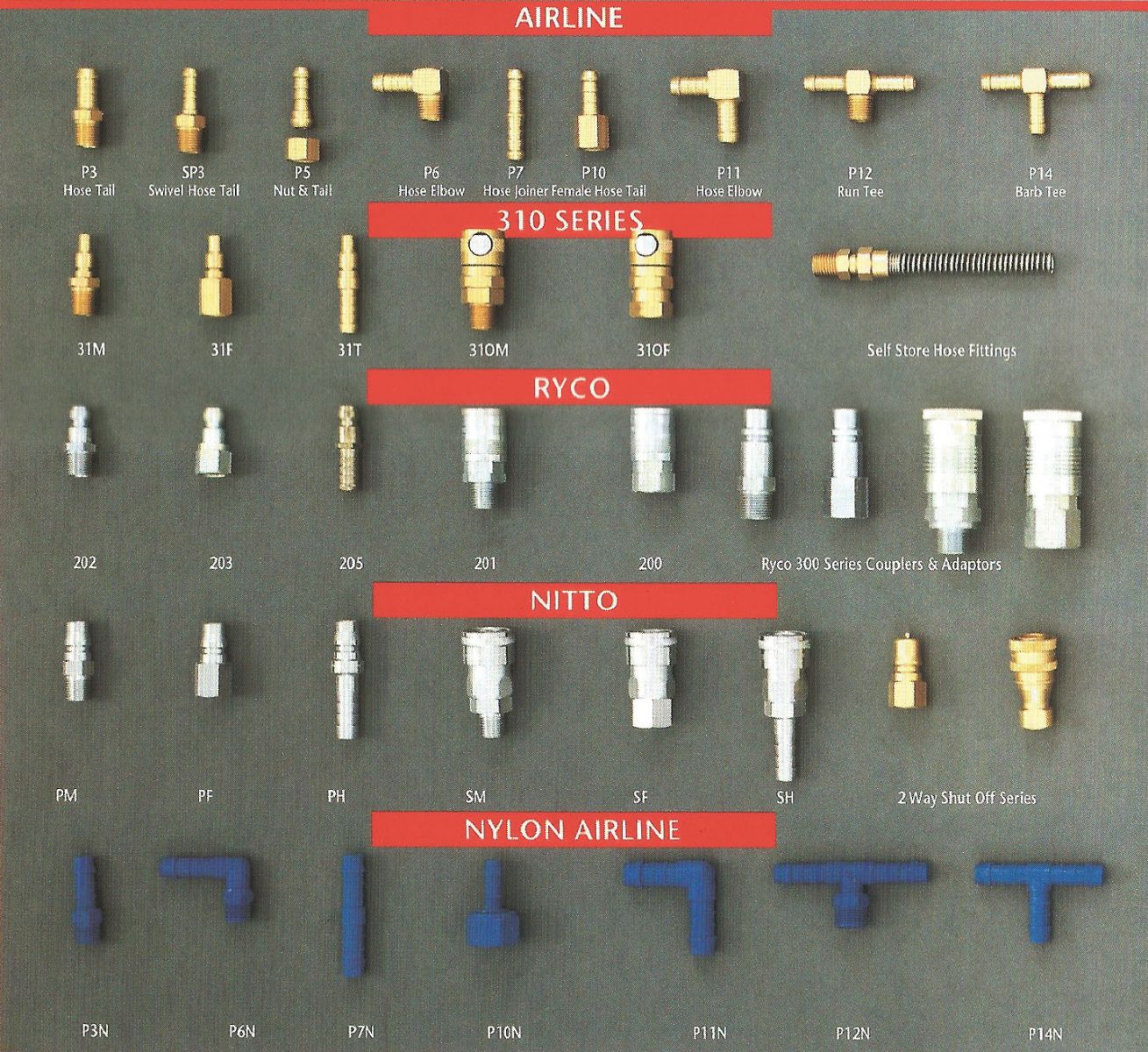

Pneumatic Air Hose Fittings At Gina Willis Blog Standard air hoses come in three sizes: 1 4 inch, 3 8 inch, and 1 2 inch. the most commonly used size is the 3 8 inch, which provides a good balance between air flow and hose flexibility. however, for high powered tools or applications that require a higher volume of air, a 1 2 inch hose may be necessary. January 18, 2024. pneumatic fittings are essential components in any system that utilizes pressurized gas to execute mechanical work, such as in automation, packaging, and manufacturing industries. they provide secure and reliable connections between hoses, tubes, and other parts of a pneumatic system, ensuring efficient operation and safety. Once a new hose assembly has been put into service, it’s important to fully inspect regularly and look for worn out fittings, clamps or damaged hoses. *always refer to osha standards 29 cfr 1926.302 and 29 cfr 1926.603 when installing and replacing pneumatic hose fittings and quick disconnects. Purpose: air fittings have several functions, for example connecting two air hoses, changing airflow direction, or connecting an air hose to an air tool. operating pressure and temperature: different pneumatic applications have various working pressure and temperatures. before selecting a fitting, check its manufacturer's specifications on max.

Comments are closed.