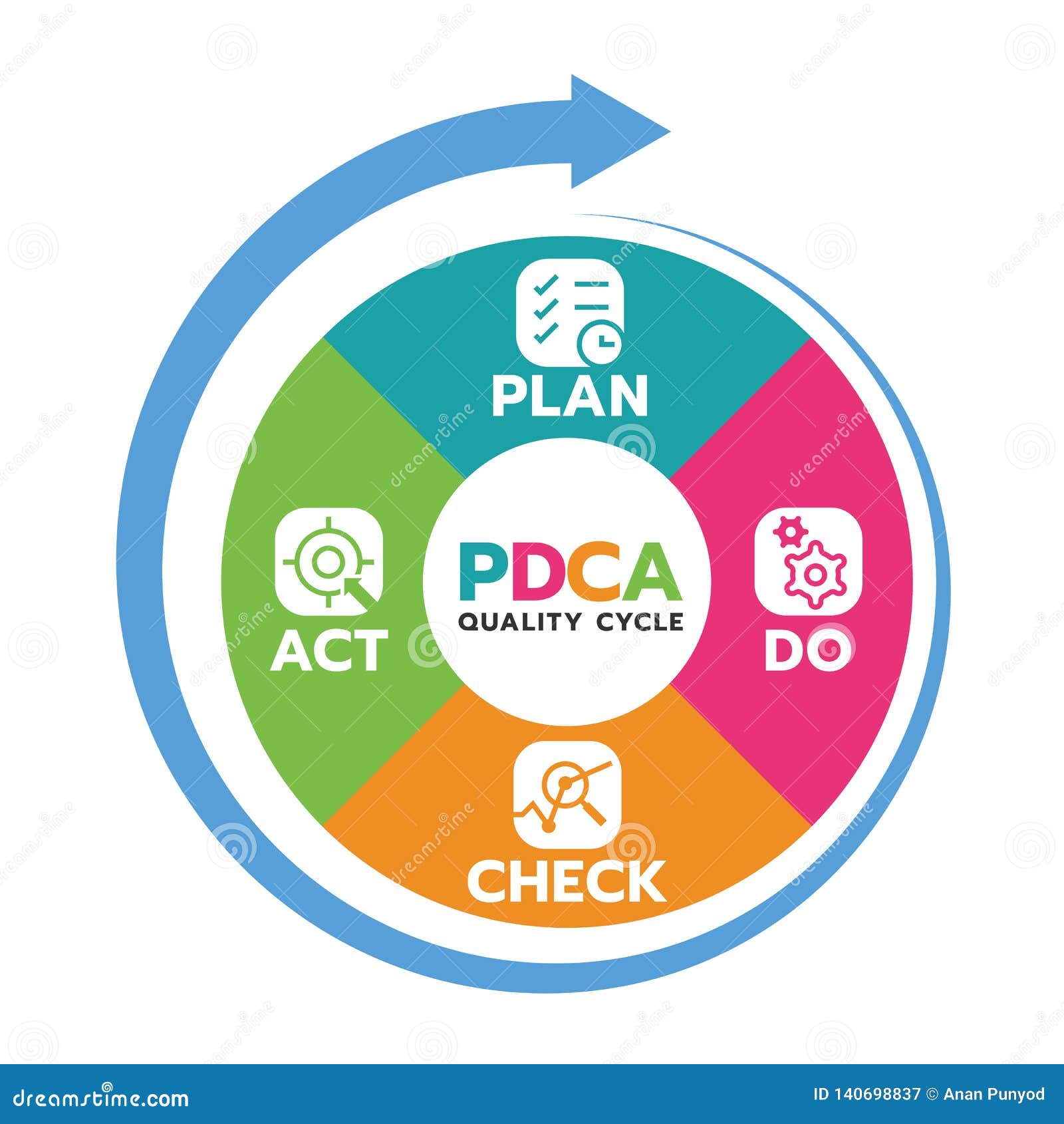

Plan Do Check Act Pdca Quality Cycle In Circle Diagram And Circl

Plan Do Check Act Pdca Quality Cycle In Circle Di Understand the evolution of these variations. the plan do check act cycle (figure 1) is a four step model for carrying out change. just as a circle has no end, the pdca cycle should be repeated again and again for continuous improvement. the pdca cycle is considered a project planning tool. figure 1: plan do check act cycle. Plan do check act cycle (pdca) is a four step, iterative by design method used for control and continual improvement of processes and products. it is also known as the plan do study act (pdsa) cycle, deming cycle, control circle cycle or the shewhart cycle. the pdca cycle (image source: shutterstock [1]) pdca is an evidence based participatory.

Pdca Quality Cycle Diagram With Plan Do Check And Actођ The pdca cycle is a four step method used to improve processes and systems. the steps are plan, do, check, and act. 2. where did the pdca cycle originate? the pdca cycle has its roots in the early 20th century, introduced by walter shewhart and further refined by dr. w. edwards deming. 3. can the pdca cycle be used outside of manufacturing?. Deming cycle can be defined as a set of four, logically connected, repetitive steps – plan, do, check (study), act – that help in continuous quality improvement and learning. the deming cycle is also known as the pdca cycle or pdsa (plan, do, study, act) cycle and is an altered version of the shewart cycle – plan, do see – that had been. Pdca or plan–do–check–act (sometimes called plan–do–check–adjust) is an iterative design and management method used in business for the control and continual improvement of processes and products. [1] it is also known as the shewhart cycle, or the control circle cycle. another version of this pdca cycle is opdca. [2]. The pdca cycle has four stages: plan — determine goals for a process and needed changes to achieve them. do — implement the changes. check — evaluate the results in terms of performance. act — standardize and stabilize the change or begin the cycle again, depending on the results. pdca is the foundation of continuous improvement or kaizen.

Comments are closed.