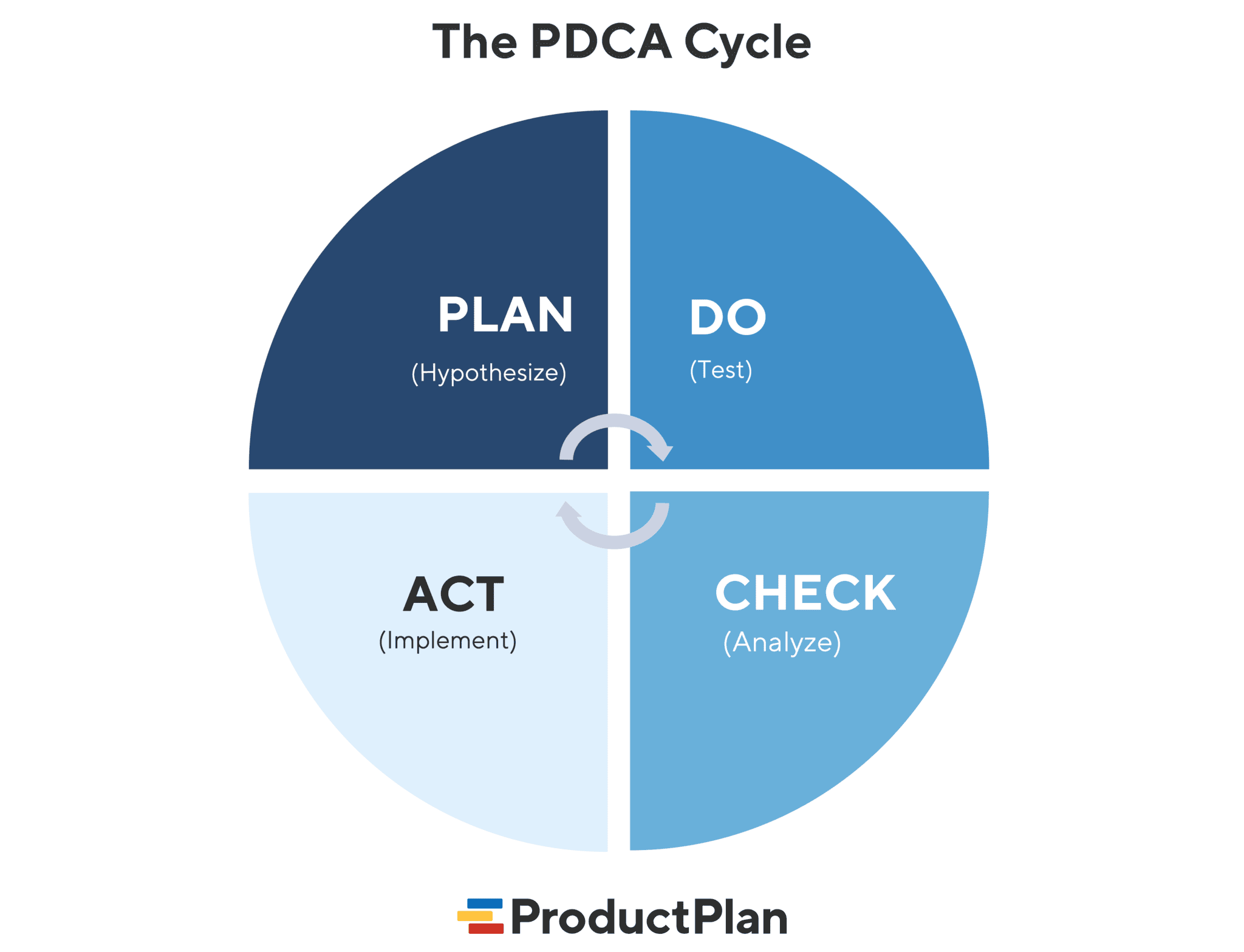

Pdca Cycle Diagram

What Is The Pdca Cycle Definition And Overview Understand the evolution of these variations. the plan do check act cycle (figure 1) is a four step model for carrying out change. just as a circle has no end, the pdca cycle should be repeated again and again for continuous improvement. the pdca cycle is considered a project planning tool. figure 1: plan do check act cycle. Learn what pdca cycle is, how it originated from the scientific method and quality improvement principles, and how to apply it in four stages with various tools. the web page also provides a diagram of the pdca cycle and examples of its application.

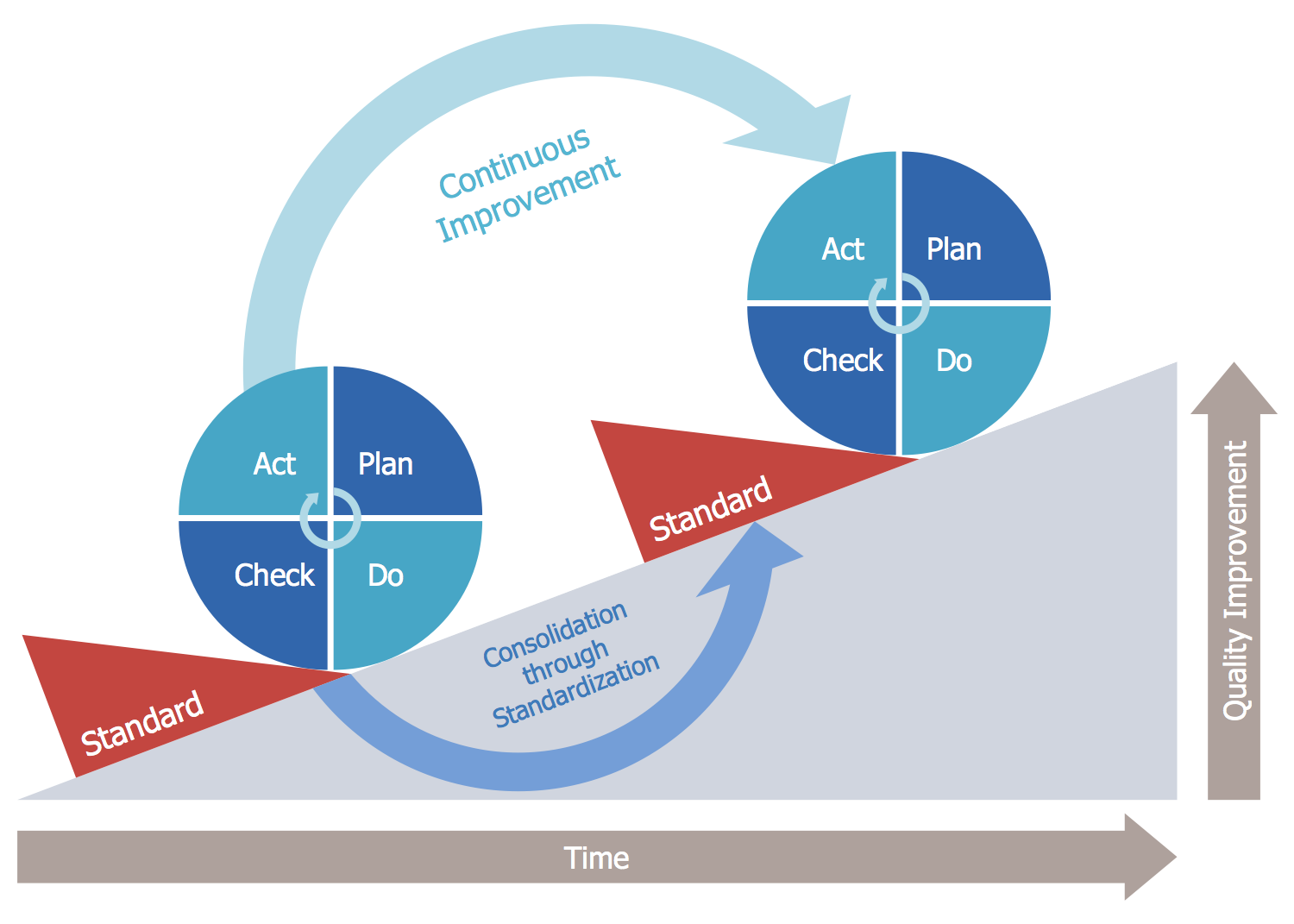

5 The Pdca Cycle For Continuous Improvement Download Scientific Diagram The pdca cycle, standing for plan do check act, is a robust framework that has underpinned continuous improvement initiatives across industries for nearly a century. developed by statistician walter a. shewhart and later refined and popularized by w. edwards deming, this iterative method fosters a culture of quality and efficiency. Pdca is a four step process of proposing, implementing, measuring and acting on a change in a process. learn about the origins, applications and examples of pdca, also known as the deming cycle or pdsa, from this resource guide. The plan do check act cycle (pdca cycle) is a four step model for systematic problem solving and continuous improvement. it offers a simple and structured way for resolving business related issues and creating positive change. this framework is widely recognized as the basis for enhancing the quality of processes, products, and services by. The pdca cycle is a that businesses can use to implement incremental change. pdca stands for plan, do, check, and act. this four step approach is the most widely used methodology for implementing continuous improvement. that is why the four steps are arranged in a circle. businesses that take this approach aim to continually repeat the process.

Taking The First Step With The Pdca Plan Do Check Act Cycle K The plan do check act cycle (pdca cycle) is a four step model for systematic problem solving and continuous improvement. it offers a simple and structured way for resolving business related issues and creating positive change. this framework is widely recognized as the basis for enhancing the quality of processes, products, and services by. The pdca cycle is a that businesses can use to implement incremental change. pdca stands for plan, do, check, and act. this four step approach is the most widely used methodology for implementing continuous improvement. that is why the four steps are arranged in a circle. businesses that take this approach aim to continually repeat the process. The plan do check act (pdca) model, also known as the deming wheel or the deming cycle, is an iterative method for continual improvement of processes, products, or services and is a key element of lean management. the pdca model was developed in the 1950s by william deming as a learning or improvement process based on the scientific method of. Pdca (plan do check act) is a problem solving iterative method for improving processes and products continuously. let’s discover each stage of the pdca cycle and the benefits it will bring to your processes. getting started. value and waste. pull systems. continuous improvement.

Plan Do Check Act Pdca Solution Conceptdraw The plan do check act (pdca) model, also known as the deming wheel or the deming cycle, is an iterative method for continual improvement of processes, products, or services and is a key element of lean management. the pdca model was developed in the 1950s by william deming as a learning or improvement process based on the scientific method of. Pdca (plan do check act) is a problem solving iterative method for improving processes and products continuously. let’s discover each stage of the pdca cycle and the benefits it will bring to your processes. getting started. value and waste. pull systems. continuous improvement.

Pdca Cycle Concept Significance Steps And Procedure Explained

Comments are closed.