Operation Of Biological Vacuum Sewage Treatment Plant Archives Marine

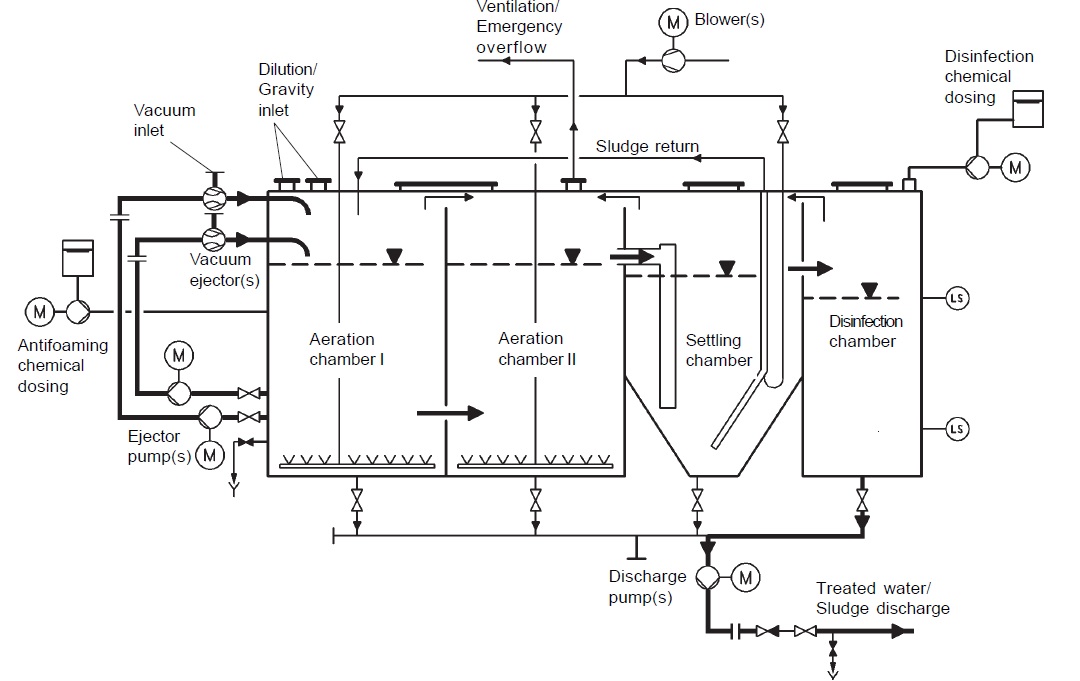

Operation Of Biological Vacuum Sewage Treatment Plant Archives Marine The biological vacuum sewage treatment plant is fully automatic in normal operation and they require low maintenance.these plants are designed to fulfill the requirements of imo marpol 73 78 annex iv and uscg 33 cfr part 159 for inspected vessels which specify discharged waste water from sewage treatment plants. Components of sewage treatment plant (stp) screen filter. the screen filter mesh is fitted on the first tank near the entrance of the sewage to the stp. it helps in removing the non sewage adulteration component such as; toilet paper, plastic paper, other solids etc, which can clog the complete system if went inside. biofilter.

Biological Sewage Treatment Ship Service Systems The aco clarimar mf biological sewage treatment plant incorporates aco mf filtration technology eliminating the requirement for settling and chlorination stages. disinfection of the treated effluent is by in line mounted uv lamp with no requirement for chemicals in any part of the aco mf process. the unique properties of the aco ‘bio sword. Jo wa bio s tp the modern marine biological sewage treatment plant. general. the new designed jowa bio stp (sewage treatment plant) is made for a modern automatic operation onboard ships in accordance with imo mepc2(vi) and meets all the requirements in marpol 73 78 annex iv. jowa bio stp can handle all types of ships, sewage, black and grey. Introduced to the sewage treatment plant after the influent sample point and after the influent flow measurement device, see figure 1. 2.4 effluent (qe) – treated wastewater produced by the sewage treatment plant, see figure 1. 2.5 flush water – transport medium used to carry sewage or other wastes from toilets or urinals to the treatment. Routine checks. 1. during daily rounds the pressure of the system should be checked and should be within the limits. 2. the air lift return should be checked to make sure the system is working properly. this is usually checked by the flow through the clear plastic pipe present on the installation. a clear sludge can be seen flowing through the.

Marine Sewage Treatment Plants Regulations And Working Marinersgalaxy Introduced to the sewage treatment plant after the influent sample point and after the influent flow measurement device, see figure 1. 2.4 effluent (qe) – treated wastewater produced by the sewage treatment plant, see figure 1. 2.5 flush water – transport medium used to carry sewage or other wastes from toilets or urinals to the treatment. Routine checks. 1. during daily rounds the pressure of the system should be checked and should be within the limits. 2. the air lift return should be checked to make sure the system is working properly. this is usually checked by the flow through the clear plastic pipe present on the installation. a clear sludge can be seen flowing through the. Marine water technologies marine water technologies sewage treatment with minimal efforts cleansewage bio is a compact, type approved marine sewage treatment plant (stp) for cargo vessels. with an incorporated moving bed bio reactor (mbbr), the cs bio requires minimal pro cessvolume, still meeting the imo mepc.227(64) discharge criteria. 5.1 testing of the operational performance of a sewage treatment plant should be conducted in accordance with the following subparagraphs. unless otherwise noted, the subparagraphs apply to testing both onboard and ashore. 5.2 raw sewage quality 5.2.1 sewage treatment plants tested ashore the influent should be fresh sewage consisting of.

Comments are closed.