Limits Fits And Tolerance Pdf

Press Fit Vs Slip Fit At Anthony Eddy Blog Evaluate limits and fits for an assembly pair 6 h7 g6 mm solution: the size 6 mm lies in the diameter step of 3 6. the fundamental tolerance unit is = 0.7327 μm tolerance for hole h7 tolerance = 16i = 12 μm the fundamental deviation h hole = zero tolerance for g6 shaft tolerance = 10i = 8 μm. Evaluate limits and fits for a pair of –diameter 6 h7 g6 solution: the size 6 mm lies in the diametral step of 3 6, therefore, d is given by – the value of fundamental tolerance unit is given by – limits of tolerance for hole h7 the standard tolerance is –16 i = 16x0.7327 = 11.72 = 12 µm the fundamental deviation h hole is –0.

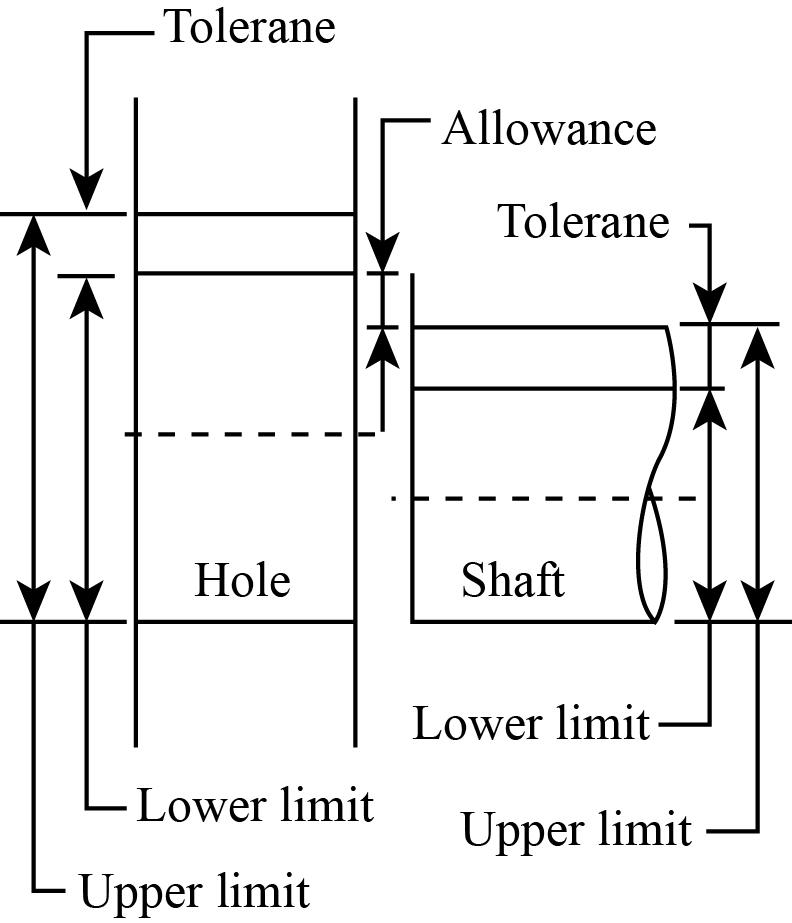

Limits Fits And Tolerances Bartleby The iso system of limits and fits is a coordinated system of hole and shaft tolerances for engineering and manufacturing used for cutting tools, material stock, gages, etc. if held to these tolerances, cutting tools, material stock, and gages are generally available throughout the world. the hole basis fits have four preferred hole tolerances. Ion of the tolerance zone in relation to the zero line.allowance: it is the intentional difference between the. ole dimensions and shaft dimension for any type of fit.size of tolerance: it is the di. the maximum and minimum limits of size.system of fitsfit is an assembly condition between ‘hole. & ‘shaft’ hole: a feature engulfing a co. 1.unilateral tolerances: if the variation permitted is at only one side of the given dimension, called unilateral tolerance. when the variation permitted is at only one side of the given dimension, then it is slightly difficult to manufacture the components. hence the cost of manufacturing will be high. ex: mating parts. Why tolerances and fits are required? due to the . inevitable inaccuracy of manufacturing methods, a part cannot be made precisely to a given dimension, the difference between maximum and minimum limits of size of a part is the tolerance. tolerance is the total amount that a specific dimension is permitted to vary.

Comments are closed.