Flow 3d Coating Flow 3d

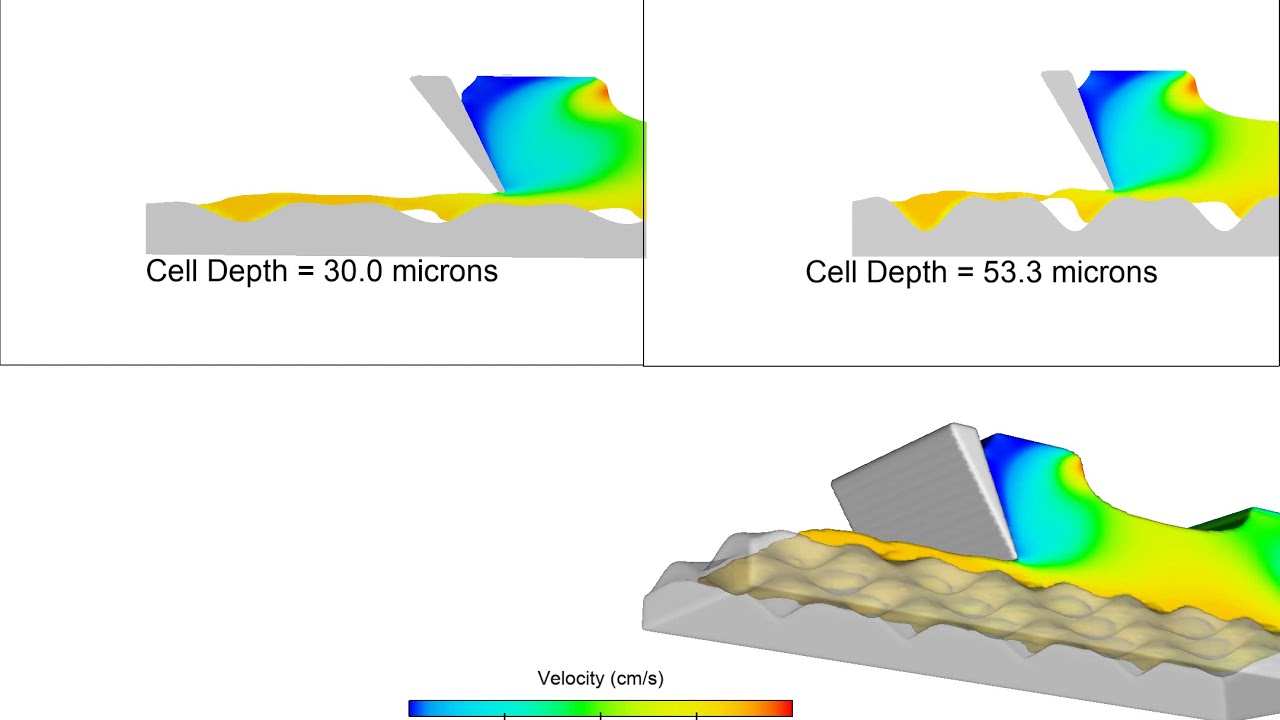

Flow 3d Coating Flow 3d The pattern, depth, and shape of the cells determine the weight and appearance of the coating on the substrate. the flow 3d simulation shown below looks at the effect of cell depth on deposition. the model compares two cell depths: 30 microns and 53.3 microns. the 30 micron cell depth allows for a much more uniform deposition, which will. Optimize product designs and reduce time to market with flow 3d, a highly accurate cfd software that specializes in solving transient, free surface problems. flow 3d ‘s complete multiphysics suite includes our state of the art postprocessor, flow 3d post. flow 3d provides a complete and versatile cfd simulation platform for engineers.

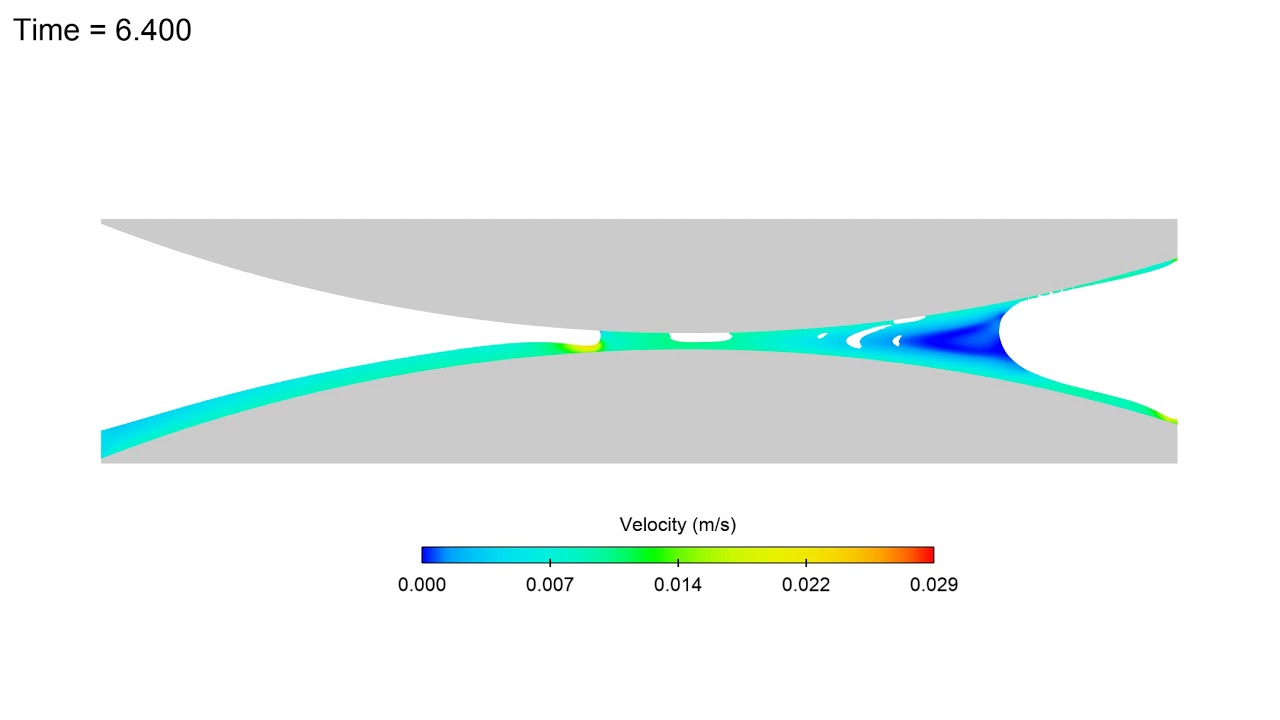

Coating Applications Flow 3d Webinar Youtube Flow 3d. flow 3d is an accurate, fast, proven cfd software that solves the toughest free surface flow problems. a pioneer in the cfd industry, and a trusted leader, flow 3d is a highly efficient, comprehensive solution for free surface flow problems with human centric support. In this simulation of a multi layer slide curtain coating process, three layers of liquid are ejected from a slot die and allowed to flow under gravity to a. This simulation shows a single layer curtain coating process. flow 3d can be used to investigate the stability of the coating process under different process. In this technical webinar, cfd engineer allyce jackman discusses how to model thin film and coating processes using the computational fluid dynamics (cfd) so.

Flow 3d Products Flow 3d Cfd Software Solutions This simulation shows a single layer curtain coating process. flow 3d can be used to investigate the stability of the coating process under different process. In this technical webinar, cfd engineer allyce jackman discusses how to model thin film and coating processes using the computational fluid dynamics (cfd) so. Coastal offshore. flow 3d accurately predicts the detail of severe storm and tsunami wave run up on coastal structures and is used for flash flood and critical structures flood and damage analysis. flow 3d is an accurate, fast, proven cfd software that solves the toughest free surface flow problems. a pioneer in the cfd industry, and a trusted. Phone: 505 982 0088 fax: 505 982 551 email: cfd@flow3d flow3d . flow 3d simulations give engineers insight into their coating designs. flow 3d’s. models simulate surface tension gradients due to temperature variations (marangoni effect), heat transfer, vaporization, condensation, solute transport and density driven flows.

Flow 3d Products Flow 3d Cfd Software Solutions Coastal offshore. flow 3d accurately predicts the detail of severe storm and tsunami wave run up on coastal structures and is used for flash flood and critical structures flood and damage analysis. flow 3d is an accurate, fast, proven cfd software that solves the toughest free surface flow problems. a pioneer in the cfd industry, and a trusted. Phone: 505 982 0088 fax: 505 982 551 email: cfd@flow3d flow3d . flow 3d simulations give engineers insight into their coating designs. flow 3d’s. models simulate surface tension gradients due to temperature variations (marangoni effect), heat transfer, vaporization, condensation, solute transport and density driven flows.

Comments are closed.