Cooling Tower Chiller Diagram

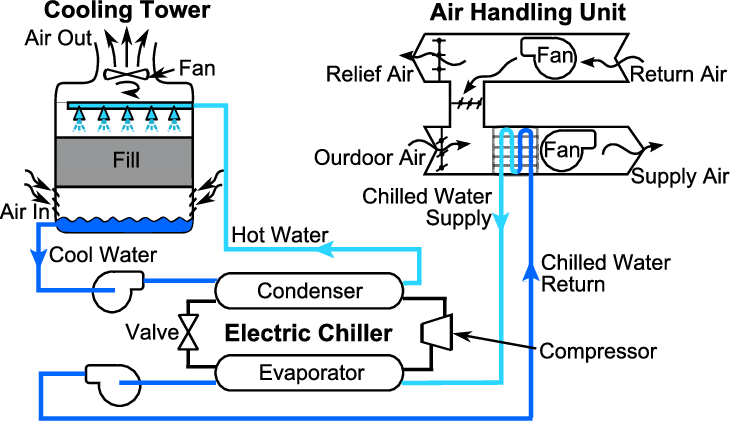

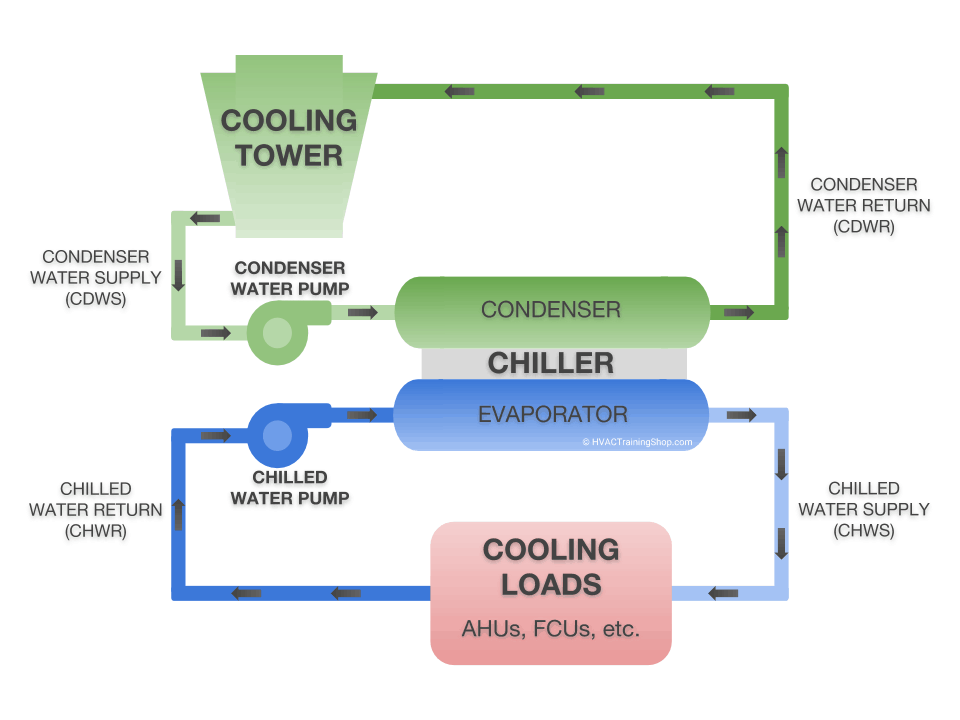

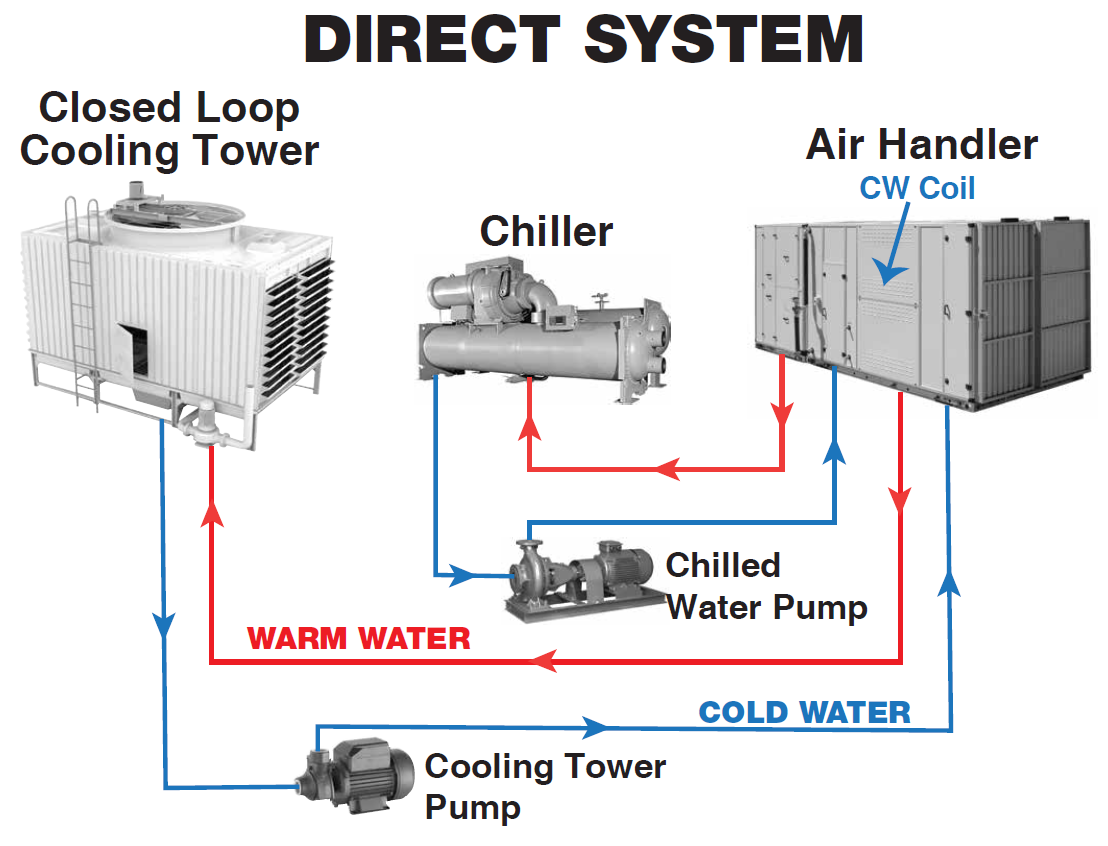

Cooling Tower And Chiller Diagram The chilled water enters the ahu fcu and passes through the cooling coil (a series of thin pipes) where it will absorb the heat of the air blowing across. the chilled water heats up and the air blowing across it cools down. when the chilled water leaves the cooling coil it will now be warmer at around 12°c (53.6°f). Condenser water return pipework [1] the cooling tower return pipework is installed to transport the warm water from the condenser side of the water cooled chiller to the cooling tower, with the flow being provided by the condenser water pumps that are installed on the supply side of the tower [tower to chiller] to move the water around the system.

An Ultimate Guide About How A Cooling Tower And Chiller Work Together Sequence of operation. when the operating fan(s) are operating at 50 percent speed, an additional fan shall be enabled and controlled at the same speed as the operating fans until all active cooling tower cell fans are enabled. when operating fans are running at minimum speed and the tower supply water temperature is five (5) degrees below the. Section2 . a general difference b w chillers and cooling tower: a water cooled chiller may be a giant piece of apparatus used in manufacturing and production center as cooperate sectors and set within the interior of a building, containing the evaporator and also the condenser. The cooling system diagram for an absorption chiller typically includes an evaporator, condenser, absorber, generator, and pump. in this type of chiller, heat is used to drive the absorption process, allowing for efficient cooling without the need for a compressor. whatever the type of chiller, understanding the cooling system diagram is. The chiller adds heat to the condenser water and the cooling tower cools it down by rejecting this into the atmosphere. the heat it rejects is all the unwanted heat from the building caused by the people, computers, sunlight, lighting etc. it must also reject the heat generated by the compressor of the chiller.

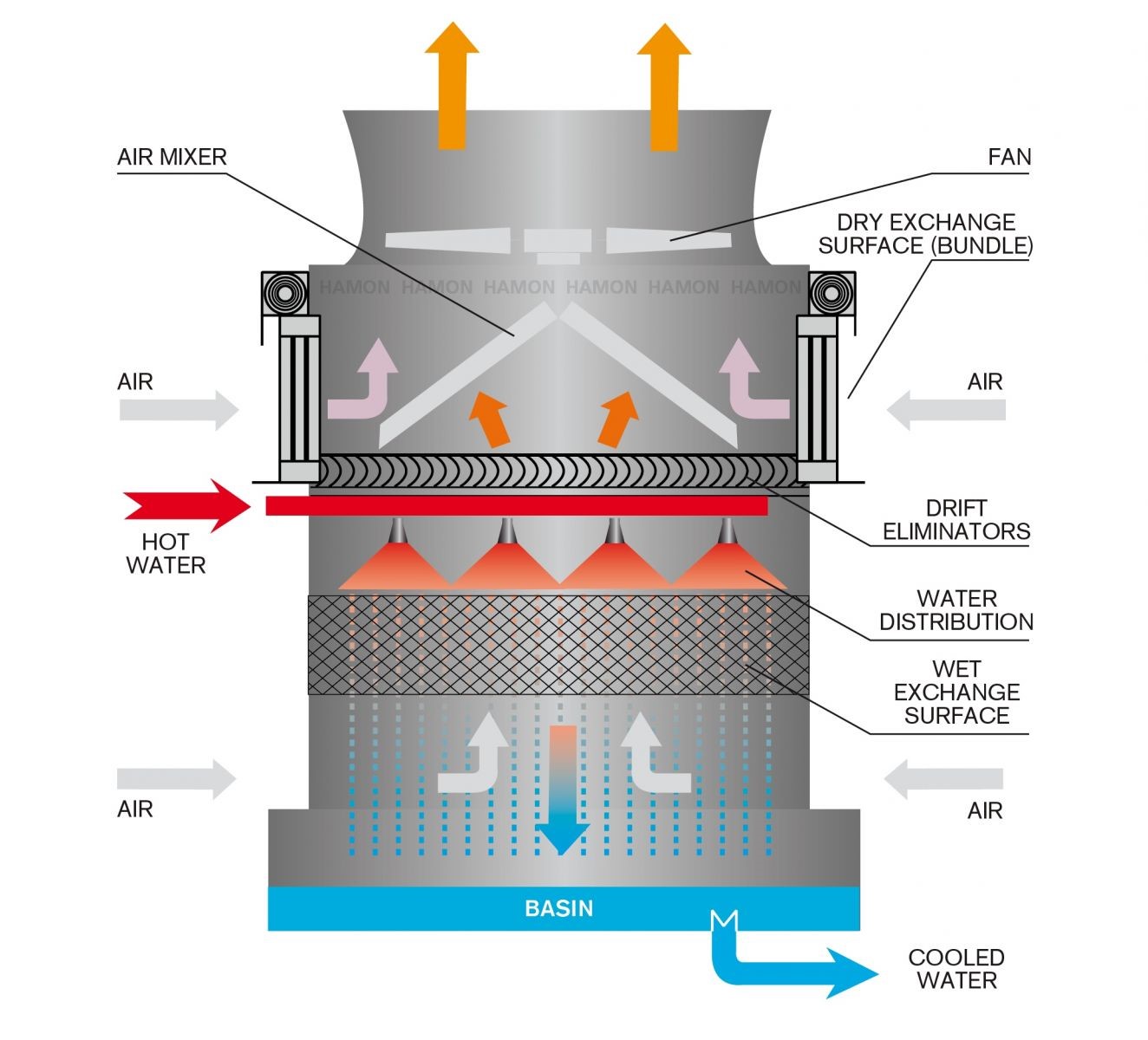

What Is A Cooling Tower Cooling Tower Basics Hvac Training Shop The cooling system diagram for an absorption chiller typically includes an evaporator, condenser, absorber, generator, and pump. in this type of chiller, heat is used to drive the absorption process, allowing for efficient cooling without the need for a compressor. whatever the type of chiller, understanding the cooling system diagram is. The chiller adds heat to the condenser water and the cooling tower cools it down by rejecting this into the atmosphere. the heat it rejects is all the unwanted heat from the building caused by the people, computers, sunlight, lighting etc. it must also reject the heat generated by the compressor of the chiller. Counterflow cooling tower diagram difference between crossflow and counterflow cooling towers: in counterflow cooling tower system processes, the air vertically flows upwards, counter to the water flow in the fill media. due to the air flowing vertically, it's not possible to use the basin's gravity flow like in crossflow towers. The water is flashed to air as it passes throughout the cooling tower. the air has been pulled using a motor driven electrical "cooling tower fan". when the air and water come into the contact, a little amount of water dissipates, producing a cooling operation. and again the cold water is pumped back to the machine that incorporates heat or the.

Cooling Tower And Chiller Diagram Counterflow cooling tower diagram difference between crossflow and counterflow cooling towers: in counterflow cooling tower system processes, the air vertically flows upwards, counter to the water flow in the fill media. due to the air flowing vertically, it's not possible to use the basin's gravity flow like in crossflow towers. The water is flashed to air as it passes throughout the cooling tower. the air has been pulled using a motor driven electrical "cooling tower fan". when the air and water come into the contact, a little amount of water dissipates, producing a cooling operation. and again the cold water is pumped back to the machine that incorporates heat or the.

Comments are closed.