Clearance Vs Tolerance

Bearing Tolerance Shaft Tolerance Tolerance Clearance Vs This is an intuitive concept to grasp a clearance fit specifies a fit where there will always be a gap in the joint between the mating shaft and hole. even at the maximum shaft and minimum hole tolerance, the shaft will be able to freely pass through the mating hole. conversely, an interference fit is a fit where there will always be overlap. Fits. a fit system is a way of specifying how much clearance or interference there is between two parts that are supposed to fit together. one of the most common fit systems is the hole shaft system, which is based on an ansi or iso standard. this system applies to cylindrical parts that have a hole and a shaft that go into the hole.

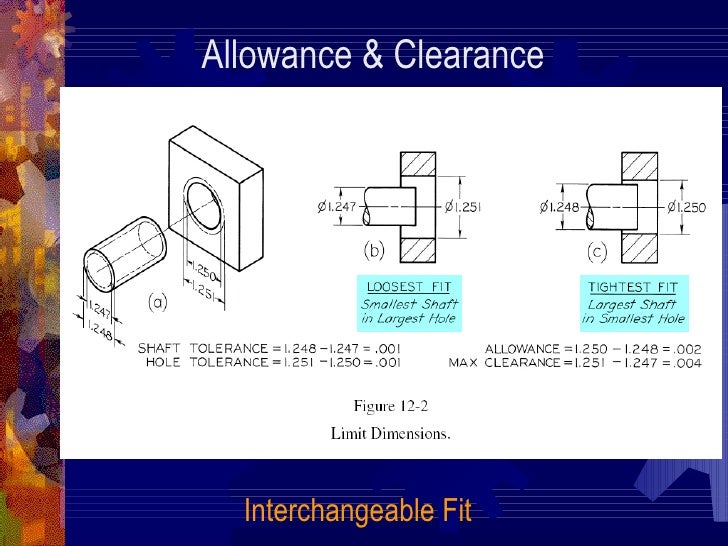

Ppt Fits Tolerances 1 Learn about the different types of fits in engineering, such as clearance, transition and interference fits, and how to choose the right one for your application. find out the tolerance grades, basis systems and examples of each fit category. The gap or lack of it between the hole and shaft is called the clearance. clearance is determined by the size difference between the parts. fits and tolerances are used to specify the size range of parts. fit the types of fits have been given names. they range from an interference fit, where the parts are purposely made to be forced together. Engineering fits are generally used as part of geometric dimensioning and tolerancing when a part or assembly is designed. in engineering terms, the "fit" is the clearance between two mating parts, and the size of this clearance determines whether the parts can, at one end of the spectrum, move or rotate independently from each other or, at the other end, are temporarily or permanently joined. Engineering tolerance is the permissible limit or limits of variation in: a physical dimension; a measured value or physical property of a material, manufactured object, system, or service; other measured values (such as temperature, humidity, etc.); in engineering and safety, a physical distance or space (tolerance), as in a truck (lorry.

Shaft Hole Tolerances For Clearance Interference Fits Misumi Mech Engineering fits are generally used as part of geometric dimensioning and tolerancing when a part or assembly is designed. in engineering terms, the "fit" is the clearance between two mating parts, and the size of this clearance determines whether the parts can, at one end of the spectrum, move or rotate independently from each other or, at the other end, are temporarily or permanently joined. Engineering tolerance is the permissible limit or limits of variation in: a physical dimension; a measured value or physical property of a material, manufactured object, system, or service; other measured values (such as temperature, humidity, etc.); in engineering and safety, a physical distance or space (tolerance), as in a truck (lorry. Tolerance analysis forms the foundation of clearance fit calculations. tolerances are the permissible variations in dimensions that components can exhibit while still meeting design specifications. tolerance analysis takes into account the variability in both the hole and shaft dimensions to ensure proper fit and functionality. Interference fit: in interference fit, the tolerance zone of the shaft goes above the tolerance zone of the hole. this means the shaft here is of large size, and the hole is of small size. to make the fits between these two, we required high force to assemble and disassemble so generally we use a hammer. another way is by using hydraulic press.

Comments are closed.