6 7 Powerstroke Cooling System Diagram Alternator

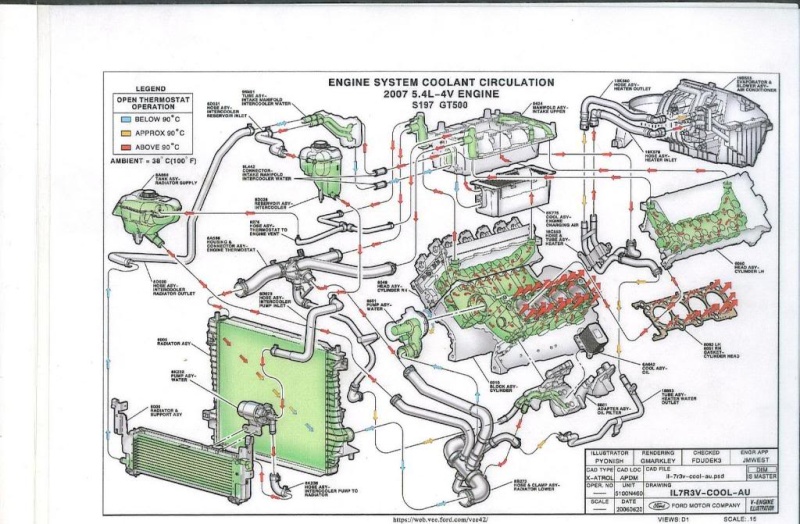

6 7 Powerstroke Cooling System Diagram Alternator 6.0 diesel w 80k 6 19 arp studs, o ringed heads stage i kc turbo 10v dc power 270xp die hards 6.4 starter, bpd waterpump fass 125 titanium w adj. press reg 3” cac pipes & csf 7106 i.c. 4” diamond eye ss exh system w two 4” ss diamond eye mufflers. ipr coolant filter w manifold cat ec 1 coolant sct x4 ecm rollback & php tunes. The cooling system diagram for the 6.7 powerstroke is a complex network of hoses, pipes, and components that work together to regulate the engine’s temperature. at the heart of the system is the radiator, which is responsible for dissipating heat from the coolant. the diagram shows the flow of coolant from the engine block to the radiator and.

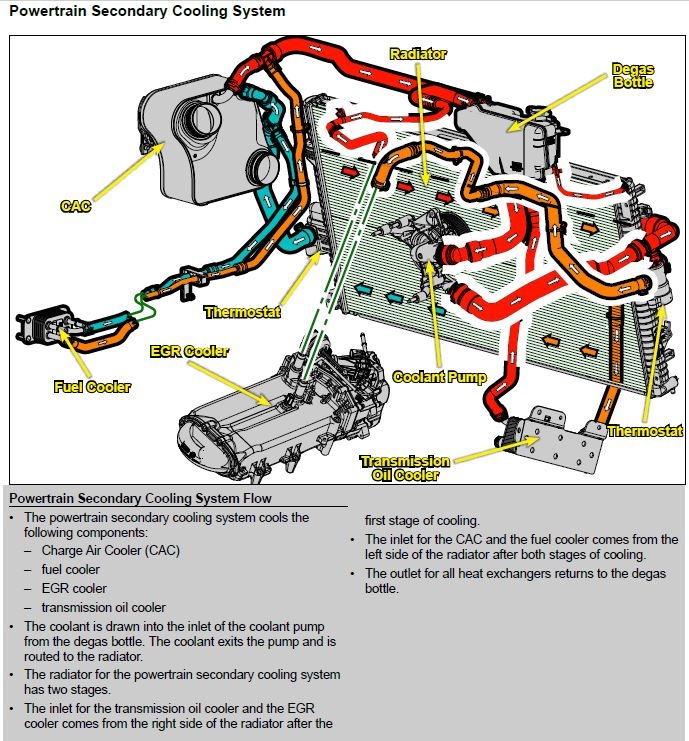

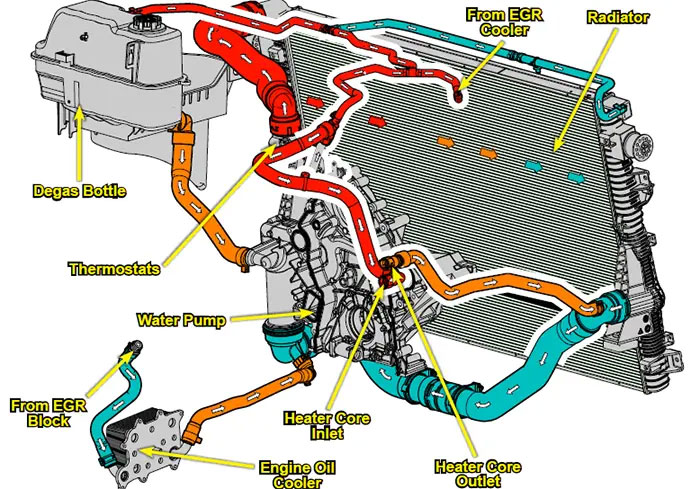

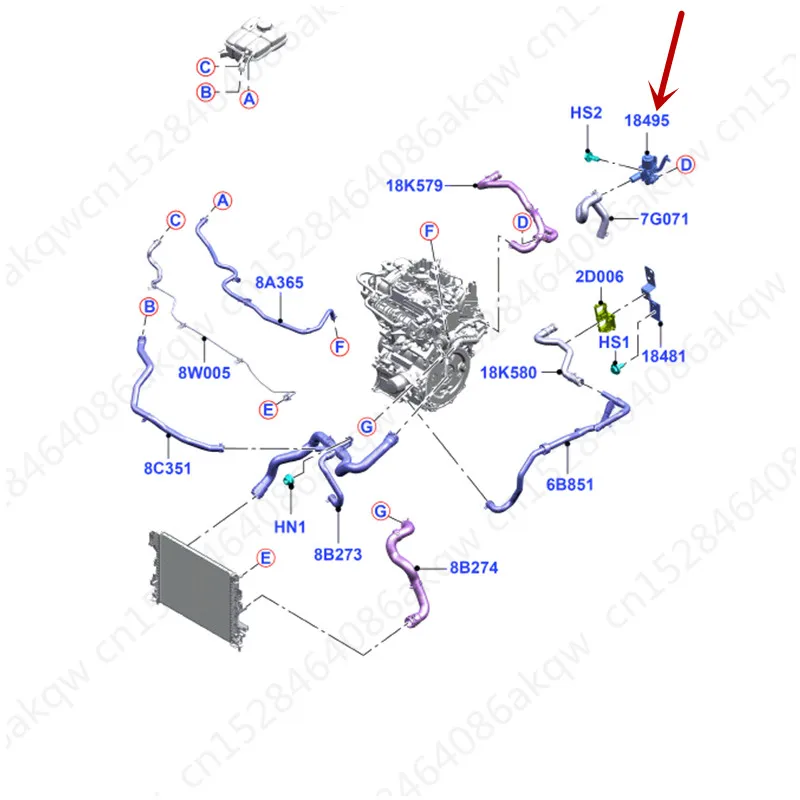

6 7 Powerstroke Cooling System Diagram Alternator The 6.7 powerstroke secondary cooling system is an important part of the truck’s cooling system. it helps to cool the engine after the truck has been turned off. the diagram below shows how the system works. the secondary cooling system consists of a radiator, a fan, and a series of hoses and pipes that connect them. The 2017 6.7 powerstroke cooling system consists of several key components that work together to regulate the engine temperature and prevent overheating. these components include the radiator, water pump, thermostat, coolant, hoses, and the degas bottle. the radiator is a heat exchanger that is responsible for cooling the engine coolant. One of the most interesting features of the 6.7l powerstroke is the use of cast aluminum reverse flow cylinder heads. air enters through the valve covers and exits from the lifter valley. as a result, the 6.7l powerstroke benefits from reduced turbo lag. overall, the 6.7 has 32 valves, equating to 4 valves per cylinder. The dual alternator system in the 6.7 powerstroke engine consists of two alternators that work in tandem to provide electrical power to various components of the vehicle. each alternator has its own set of pulleys, and the belt connects these pulleys, enabling them to rotate when the engine is running. the belt diagram outlines the specific.

The Ultimate Guide To Understanding The 6 7 Powerstroke Cooling System One of the most interesting features of the 6.7l powerstroke is the use of cast aluminum reverse flow cylinder heads. air enters through the valve covers and exits from the lifter valley. as a result, the 6.7l powerstroke benefits from reduced turbo lag. overall, the 6.7 has 32 valves, equating to 4 valves per cylinder. The dual alternator system in the 6.7 powerstroke engine consists of two alternators that work in tandem to provide electrical power to various components of the vehicle. each alternator has its own set of pulleys, and the belt connects these pulleys, enabling them to rotate when the engine is running. the belt diagram outlines the specific. 2) egr cooler clogging. exhaust gas recirculation (egr) cooler problems are also one of the most common on the ford 6.7 powerstroke. it’s not as common as with the previous 6.0l and 6.4l engines, though. ford actually changed the design of the egr system on the 6.7l engine. the valve lies in the hot side now. To be on the safe side, periodically check the antifreeze every six months. one crucial often overlooked component of the coolant system is the radiator cap. the radiator cap on the powerstroke engine is rated at 16 psi. this is for both the 7.3l and 6.0l versions.

Ford 6 7l Power Stroke Diesel Engine Specs Info 2) egr cooler clogging. exhaust gas recirculation (egr) cooler problems are also one of the most common on the ford 6.7 powerstroke. it’s not as common as with the previous 6.0l and 6.4l engines, though. ford actually changed the design of the egr system on the 6.7l engine. the valve lies in the hot side now. To be on the safe side, periodically check the antifreeze every six months. one crucial often overlooked component of the coolant system is the radiator cap. the radiator cap on the powerstroke engine is rated at 16 psi. this is for both the 7.3l and 6.0l versions.

6 7 Powerstroke Secondary Cooling System Diagram

Comments are closed.