5 Step Kaizen Program

What Is Kaizen 6 Steps To Apply Kaizen Method In An Effective Company This approach can be applied to any area of life, from personal growth to professional development. in this blog post, i will provide a step by step guide to the kaizen method for continuous improvement. step 1: identify areas for improvement. the first step in the kaizen method is to identify areas for improvement. Kaizen is a structured, continual process for improving products, services and systems. kaizen touches every step of the production process and covers equipment, methods, materials and people. it is an organization wide approach that involves every person in a company, from the owners and managers to employees and contractors.

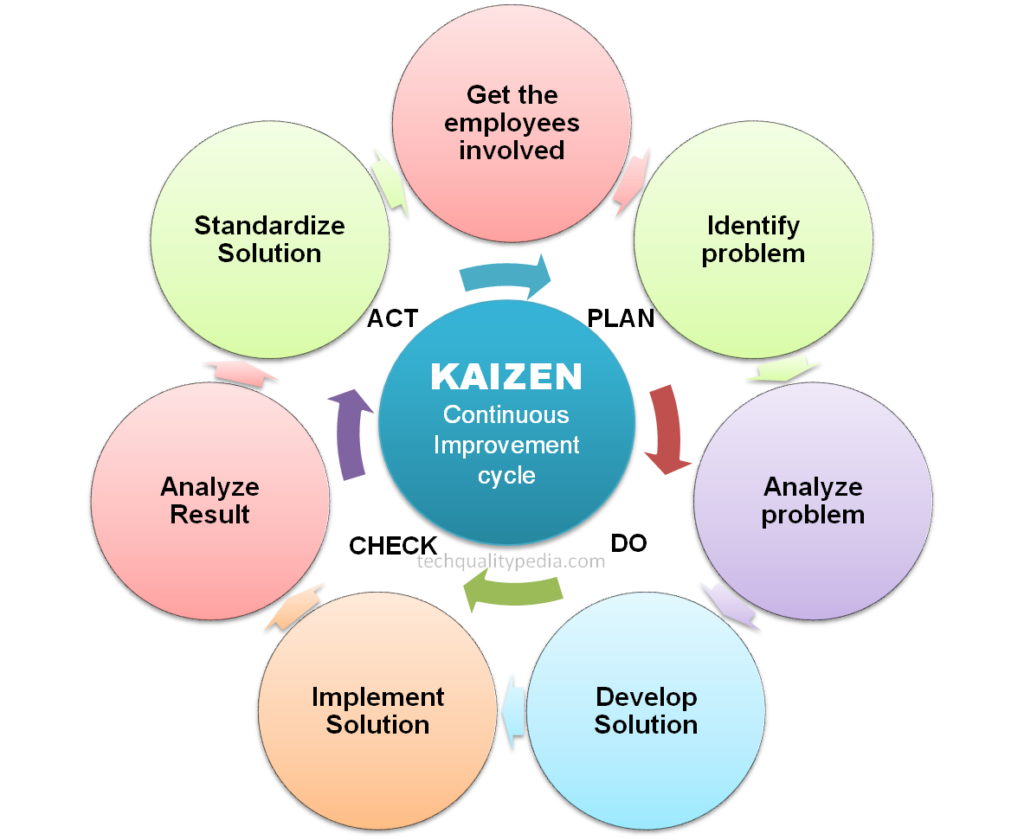

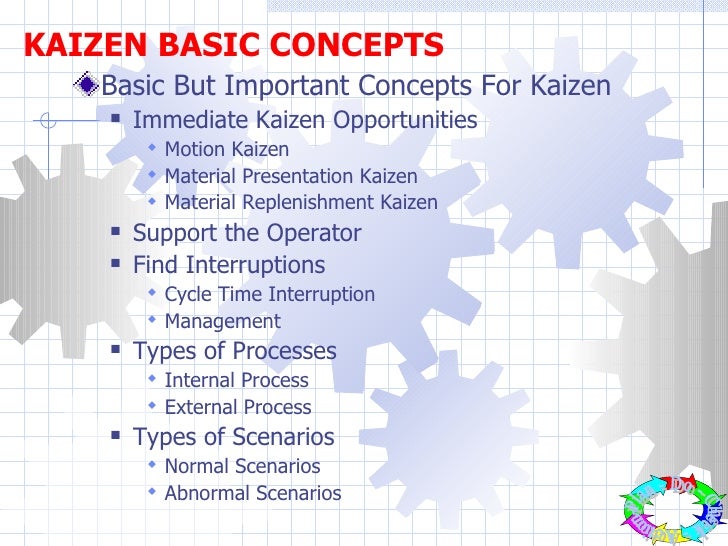

Kaizen Means Kaizen Definition Kaizen Process Objectives Examples Riset This process is designed to empower people and engage team members in the work process. according to the information on toyal’s website, the company uses the kaizen principle to underpin the aim of forever thinking about the next, learning from the past, and improving the toyota production system. 2. nestle. The kaizen approach to continuous improvement is guided by 5 key principles: sort, set in order, shine, standardize, and sustain. each principle aims to streamline processes, increase productivity, and maintain a safe and organized work environment. the kaizen 5s framework involves five steps for organizing and efficiency: sort, set in order. 1. step by step guide to successful kaizen implementation . mastering operational excellence is not easy as it requires a deep conceptual understanding of kaizen and applying it to real world business scenarios. here are the key steps for implementing kaizen: step 1: identify areas for improvement. The kaizen process. the continuous cycle of kaizen activity has six phases: 1. identify a problem or opportunity 2. analyze the process 3. develop an optimal solution 4. implement the solution 5. study the results and adjust 6. standardize the solution. figure 1.continuous improvement cycle.

5 Step Kaizen Program 1. step by step guide to successful kaizen implementation . mastering operational excellence is not easy as it requires a deep conceptual understanding of kaizen and applying it to real world business scenarios. here are the key steps for implementing kaizen: step 1: identify areas for improvement. The kaizen process. the continuous cycle of kaizen activity has six phases: 1. identify a problem or opportunity 2. analyze the process 3. develop an optimal solution 4. implement the solution 5. study the results and adjust 6. standardize the solution. figure 1.continuous improvement cycle. Kaizen is a compound of two japanese terms, kai meaning “change” and zen meaning “good”. this term defines the idea of continuous improvement which is the basis of lean thinking. overall, kaizen, or continuous improvement, is the idea that small, iterative changes to a process can compound to have massive benefits in the long term. The kaizen process. the kaizen process is based on the pdca (plan do check act) cycles. this means that an organization first identifies areas for improvement, develops a plan to make changes, implements the changes, and then checks the results to see if further improvements can be made. this continuous cycle of improvement leads to a culture.

Process Of Kaizen Kaizen Change Management Process Improvement Kaizen is a compound of two japanese terms, kai meaning “change” and zen meaning “good”. this term defines the idea of continuous improvement which is the basis of lean thinking. overall, kaizen, or continuous improvement, is the idea that small, iterative changes to a process can compound to have massive benefits in the long term. The kaizen process. the kaizen process is based on the pdca (plan do check act) cycles. this means that an organization first identifies areas for improvement, develops a plan to make changes, implements the changes, and then checks the results to see if further improvements can be made. this continuous cycle of improvement leads to a culture.

5 Steps Kaizen

Comments are closed.